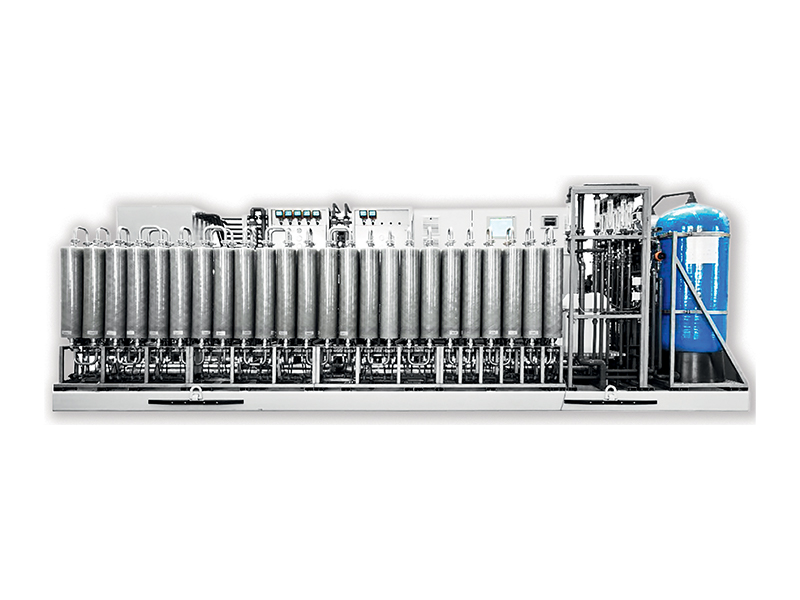

The industry faces huge wastewater generation with stringent water reuse norms. We understand specific needs like spent wash and other critical treatments to offer a comprehensive Zero Liquid Discharge. As a complete Zero Liquid Discharge (ZLD) solution provider for the distillery industry, we specialize in addressing the complex water management needs of distillery facilities. Leveraging our expertise in advanced membrane technologies, evaporation techniques, and brine concentration processes, we deliver customized solutions tailored to the unique requirements of each client. Our comprehensive approach ensures maximum water recovery, regulatory compliance, and operational efficiency, enabling distilleries to achieve sustainable and cost-effective water management. By minimizing liquid waste and promoting water reuse, we help distilleries enhance their environmental stewardship and operational resilience.