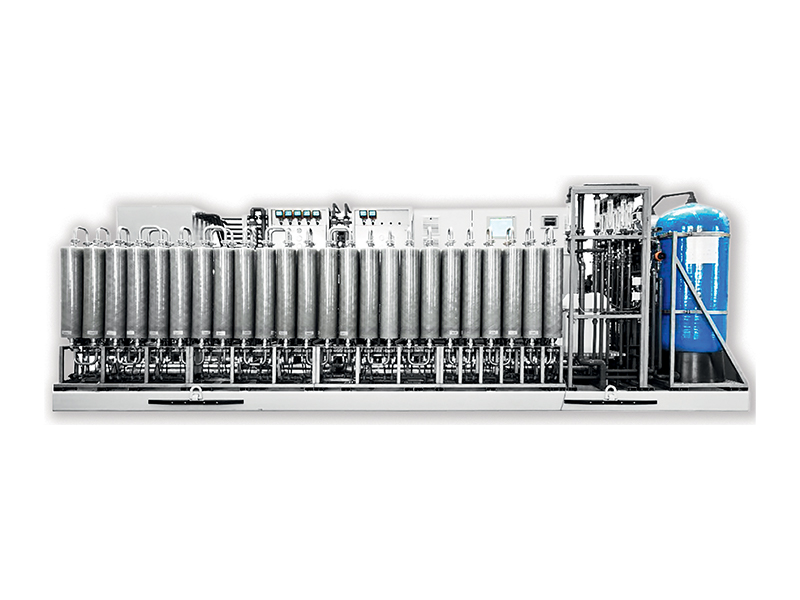

The manufacturing process has one of the highest water consumption. We understand the varied characteristics of effluents from the numerous processing units to significantly reduce freshwater consumption and associated costs.

As a premier Zero Liquid Discharge (ZLD) solution provider for the textile industry, we understand the critical importance of effective water management in textile manufacturing. Our tailored solutions are designed to meet the diverse and complex water treatment needs of textile facilities, ensuring sustainable and compliant operations. With our advanced membrane technologies, evaporation techniques, and brine concentration processes, we deliver comprehensive and customized solutions across various streams of textile production, such as Dyeing, finishing, printing, washing, and yarn and fabric production.