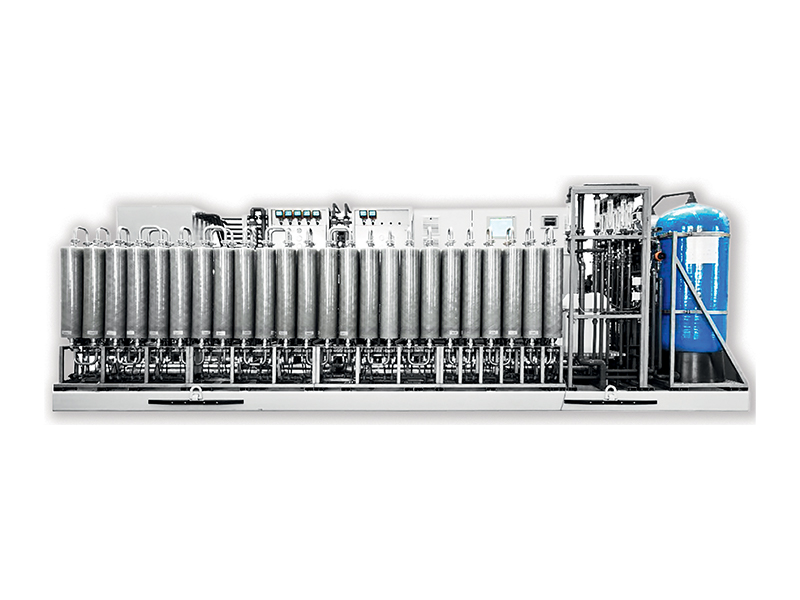

Tannery wastewater is highly complex, characterized by high contents of varied contaminants and variable Ph. We understand these variables with high water usage requirements to provide the best solutions.

We specialize in providing comprehensive ZLD solutions tailored for the tanneries industry, addressing water management challenges effectively. Our expertise in advanced membrane technologies, evaporation processes, and brine concentration ensures complete liquid discharge elimination. By customizing ZLD systems to meet specific needs, we enable tanneries to achieve regulatory compliance and environmental sustainability. With our solutions, wastewater is treated and recycled efficiently, minimizing environmental impact and reducing freshwater consumption. Partner with us to implement cutting-edge ZLD solutions, ensuring responsible water management and operational efficiency in your tannery operations.