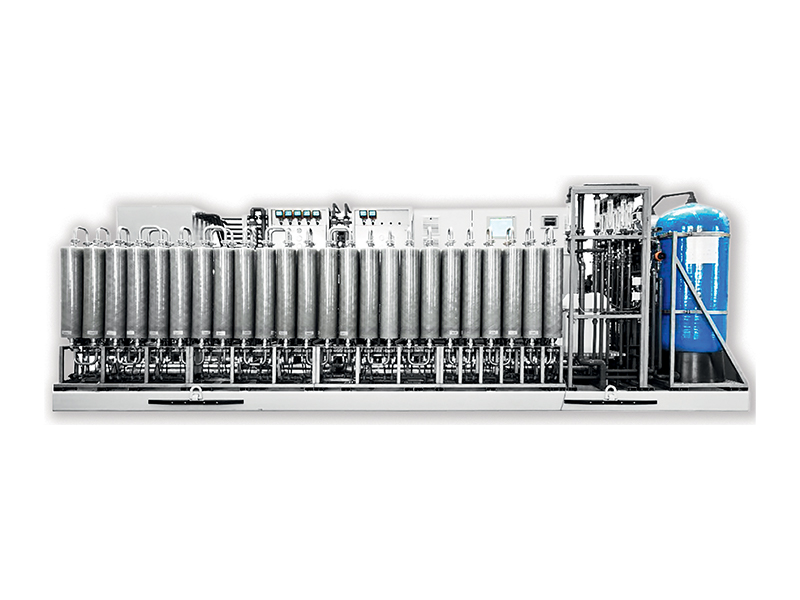

The wastewater arising from the process needs immediate attention to meet legal compliance and environmental conservation norms. We offer various technologies to support water reuse back into the processes.

As a leading provider of Zero Liquid Discharge (ZLD) solutions, we specialize in addressing the specific water management challenges faced by the paint industry. Our tailored ZLD systems incorporate advanced membrane technologies, evaporation techniques, and brine concentration processes to ensure efficient treatment and management of wastewater. By partnering with us, paint manufacturers can achieve complete liquid discharge elimination, ensuring compliance with environmental regulations and promoting sustainable practices. Our ZLD solutions minimize environmental impact, reduce discharge costs, and demonstrate a commitment to responsible paint manufacturing. Trust us to deliver innovative and efficient ZLD solutions that meet the unique needs of the paint industry while fostering environmental stewardship.